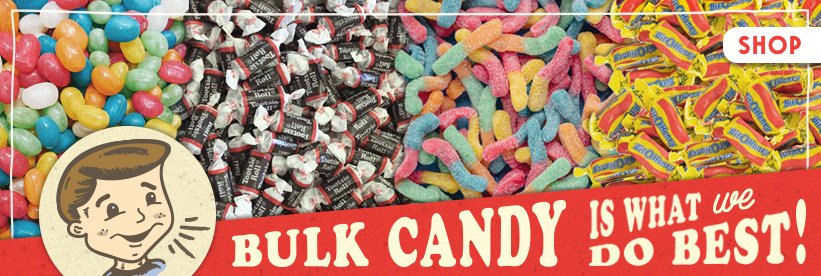

Customer Favorites

-

Cadbury Creme Eggs - 48 / BoxSpecial Price $53.17 Regular Price $88.61

Cadbury Creme Eggs - 48 / BoxSpecial Price $53.17 Regular Price $88.61

Talk To Us

Can't find what you're looking for?

Please contact us:

Connect With Us

We're social by nature and always up to something. Follow us and see!

Sign Up For The Newsletter

Well send you all the latest scoops, including bulk candy coupons, deals and new products.

Newsletter